Over the past few years, silicon carbide (SiC) has emerged as an attractive alternative to silicon as a semiconductor base material because it offers improved performance, most notably realized in applications requiring high power. Although various industrial devices now incorporate SiC, the majority of emerging demand will come from applications in electric-vehicle (EV) powertrains in the form of metal-oxide-semiconductor field-effect transistors (MOSFETs).

In an October 2023 article, McKinsey estimated that the SiC device market would grow at a 26 percent CAGR through 2030.1 More recently, however, EV adoption rates have slowed across many regions, largely driven by regulatory changes and shifting consumer preferences. This development has created a few questions about the future SiC wafer market. Should current SiC wafer demand projections be adjusted downward? Will all the announced wafer capacity come online? And to what extent might any shifts allow supply to meet or exceed short-term or long-term demand?

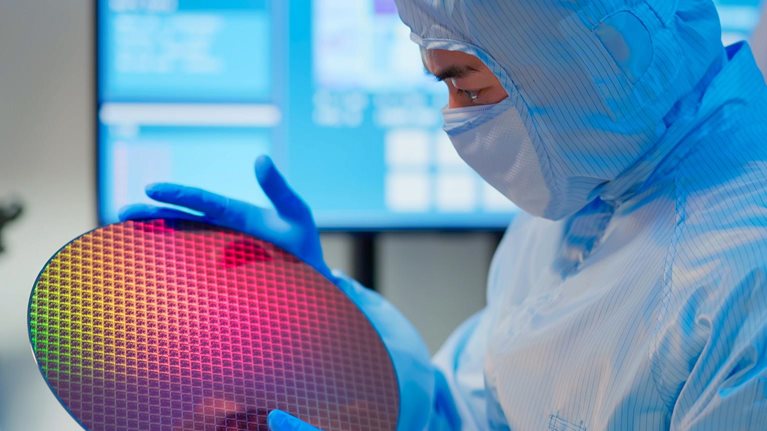

To gain greater insight into SiC wafer market trends, we evaluated the critical factors that can affect supply and demand. One notable difference in our approach compared with the methodologies used in other forecasts is that we included a nuanced examination of wafer yield2 rates (the number of wafers produced that meet acceptable quality standards). Yield rates are often held in highest confidence across the industry and may be difficult to compare across companies. Therefore, most forecasts estimate supply based on nameplate capacity, which is the maximum theoretical output of a wafer manufacturing site.

Nameplate capacity does not factor in yield losses or consider whether wafers will meet specific quality grades. Consequently, production estimates based on nameplate capacity will overestimate supply for some of the most yield-sensitive segments. Automotive-grade MOSFET wafers, especially those for EVs, have the lowest yield because they must undergo a complex production process and meet the most stringent quality guidelines.

Given the deep uncertainty about yield and other factors, we created multiple market scenarios for 2027 that incorporated different supply-and-demand inputs. The scenario projections varied widely, ranging from a SiC oversupply to equilibrium to undersupply. While it is too early to determine which scenario is most likely to materialize, our analysis may help industrial leaders understand the most important forces influencing the SiC market, especially wafer yield.

The benefits and challenges of SiC

Before diving into the market forces, it’s critical to understand the inherent attributes of SiC, which give it several advantages over silicon, especially in use cases with high power requirements, such as EV inverters:

- Higher efficiency. Energy losses are lower, and thermal management is less expensive because of the peripheral components involved.

- Longer lifetime. Better thermal conductivity allows SiC chips to function across higher temperature ranges and endure higher stress levels, prolonging lifetime.

- Smaller form factor. SiC may deliver equivalent functionality to silicon in a smaller package with less semiconductor material, decreasing the number of semiconductors in high-power devices.

- Simpler design. Higher power ranges allow new designs on the system level and fewer passive elements, contributing to reduced costs and waste over the long term.

SiC wafers, as well as the corresponding chips manufactured using these wafers, enable multiple applications and come in three basic grades.3 Diodes, which are built on the lowest-quality SiC wafers, are the simplest in function and allow current to flow in one direction. MOSFETs, which are a type of transistor that requires higher SiC wafer quality, are more complicated and allow current to switch direction. Automotive-grade MOSFETs require wafer quality and transistors that meet stringent specifications, necessitating very low defect rates.

While a significant increase in SiC wafer capacity is expected over the next five years based on industry-wide capacity expansion announcements, the exact mix and functionality of SiC capacity is unknown and might be insufficient to meet the increasing demand from EV applications.

Automotive-grade MOSFET wafers, which are the most difficult to manufacture and in highest demand, are likely to be particularly scarce. Compounding the problem, companies do not disclose the share of automotive-grade MOSFET wafers being produced, making it impossible to get an accurate estimate of future supply. The only certainty is that the number of automotive-grade MOSFET wafers will be significantly lower than the announced manufacturer nameplate capacity.

New SiC demand trends amid a battery electric vehicle slowdown

SiC is particularly critical to the battery EV (BEV) industry because it enhances performance to a greater extent than silicon by extending vehicle range, reducing charging time, and reducing the number of semiconductors in vehicles.

Although most BEVs still use silicon solutions in their powertrains, OEMs are transitioning to purpose-built SiC devices in second- and third-generation vehicles, some of which have 800-volt systems. With their high power requirements, these BEVs benefit more from SiC than silicon. By 2027, over 50 percent of BEVs could rely on SiC powertrains, compared with about 30 percent today. That shift, combined with the growing preference for BEVs among EV buyers, will increase SiC demand.

Changes in BEV production

Although demand for BEVs is now growing more slowly, the exact impact is difficult to predict because so many factors influence OEM manufacturing decisions. Acknowledging this uncertainty, the McKinsey Center for Future Mobility (MCFM) has created different EV growth scenarios based on different assumptions about regulations, technology, availability of raw materials, and consumer behavior. The three MCFM scenarios considered in our analysis are as follows4:

- Fading momentum. In this scenario, EV costs decline less than anticipated, consumer demand drops, vehicle range is limited, and regulations do not strongly promote the transition from internal combustion engine (ICE) vehicles.

- Current trajectory. This scenario assumes that the most recent demand curve, production capacity, and EV regulations will persist.

- Further acceleration. Demand soars above the current trajectory in this scenario because of favorable policies, lower prices, greater availability of raw materials, higher vehicle production, and increased consumer interest.

The further-acceleration scenario, which is the most optimistic, assumes that demand soars beyond the current trajectory. If it materializes, 29 million BEVs will be on the road in 2027 (Exhibit 1). This is far higher than the projections for the current-trajectory scenario (23 million) and the fading-momentum scenario (17 million).

For passenger vehicles, MCFM’s 2024 estimates for BEV production in all major markets are lower than the 2023 estimates, largely because of likely declining consumer interest, high vehicle prices, and decreased incentives for EV purchases in the European Union and the United States. China, the world’s largest EV market, is expected to see a somewhat more modest reduction in BEV production of passenger vehicles. Exhibit 2 shows the expected production in the current-trajectory and fading-momentum scenarios.

Overall, BEVs are expected to account for about 27 percent of passenger vehicles produced globally by 2027 if the current growth trajectory continues. There will be significant regional variations, however. For instance, BEVs may account for 42 percent of passenger vehicles produced in China, while levels in the United States could be 24 percent. This pattern is consistent with past years, when China was also the largest EV producer.

Varying forecasts for total SiC demand

In our analysis, we kept future nonautomotive SiC demand constant but considered different possibilities for automotive SiC demand based on MCFM’s estimates for BEV production in 2027.

In MCFM’s fading-momentum scenario, demand for 150-millimeter (mm)-equivalent SiC wafers is expected to reach 3.7 million in 2027. This is much lower than the SiC wafer demand estimates for the current-trajectory scenario (4.7 million) and the further-acceleration scenario (5.7 million).

High defect rates and lower yields complicate supply estimates

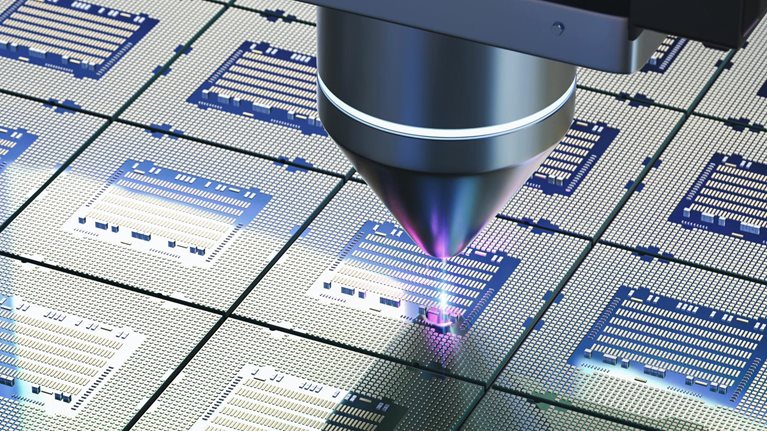

Over the past few years, enthusiasm about BEVs was so great that new and incumbent SiC wafer providers have collectively announced that they plan to increase production capacity of 150-mm SiC wafer equivalents from 2.8 million in 2023 to 10.9 million in 2027—a more than threefold increase. It is important to note, however, that this supply estimate does not factor in yield loss.

When we analyzed future supply announcements, we looked at incumbents and emerging suppliers separately (Exhibit 3). The leading incumbent companies often have a strong head start—about five to ten additional years of engaging in SiC learning cycles—and thus are more likely to see higher yield performance. Incumbents produced about 1.9 million 150-mm SiC wafer equivalents in 2023 and have announced that they plan to have additional capacity of about 5.4 million come online by 2027.

Emerging suppliers that have not been through as many learning cycles as incumbents have announced their intention to expand capacity from 0.9 million 150-mm wafer equivalents in 2023 to about 3.6 million 150-mm wafer equivalents in 2027. These companies might have lower yields than incumbents, however, since they have less experience.

Determining the actual supply

As with demand, several factors could influence how supply actually evolves and whether companies meet or fall short of their announced targets. We therefore developed three different scenarios to estimate the actual 2027 supply:

- Commoditization. In this scenario, SiC suppliers improve wafer yield levels significantly, bringing the average to 60 percent in 2027. This would be in line with the historical levels achieved by the industry’s top performers and would result in a supply of 5.5 million wafers.

- Announced ramp-up. This scenario assumes that both incumbent and emerging manufacturers achieve their announced production targets, with yields remaining in line with current levels of about 48 percent. The supply of wafers would be 4.7 million.

- Technology delays. This scenario assumes that established manufacturers achieve announced production targets, while emerging manufacturers struggle to increase production meaningfully. Wafer supply would be only 3.7 million.

Additional considerations that could affect SiC supply

Our analysis does not factor in all possible headwinds facing the industry. For instance, capacity increases announced by manufacturers may not come to fruition in the planned time frame. In addition, our estimates for the useable supply of SiC wafers assume that they will be 150 mm, but all companies are expected to experiment with 200-mm capabilities and at least 10 percent of announced supply will be in the form of 200-mm wafers. The manufacturing process for these wafers is significantly more difficult, which can create additional complications. If we considered 200-mm wafers in our analysis, the yield rate would have been lower.

Eventually, however, the shift to 200-mm wafers might be a tailwind. The manufacturers that succeed in mastering the 200-mm evolution will realize a much lower cost per square mm for wafers produced, and theoretically better yields in the long run. This, in turn, will give them a cost advantage relative to manufacturers that continue to rely on 150-mm processes. Since 200-mm wafers contain more dies per mm, fewer will be required to satisfy demand.

Also important is that yield rates are lower for wafers that must meet the most stringent quality grades, such as automotive MOSFETs, than they are for other grades, such as diodes. Our current scenarios do not differentiate wafers by grade; instead, they assume that all production yields for incumbent and emerging companies will meet the stringent quality standards of the automotive industry. This is unlikely to occur, since much of today’s supply does not meet automotive standards, and it is highly unlikely that all supply coming online will meet that bar.

Other issues that could affect wafer supply are discussed in the sidebar, “Further uncertainty introduced by engineered wafers.”

Monitoring the supply-and-demand trends that shape the SiC market

Industry stakeholders have differing opinions about where SiC supply and demand will meet. Our analysis is intended to help illuminate the critical factors facing the SiC industry and to provide a perspective about the range of all possible outcomes (Exhibit 4).

Our scenarios suggest different supply-and-demand outcomes. Consider the announced ramp-up scenario for supply, in which incumbents and emerging companies meet their targets and yields remain at current levels. In this scenario, supply and demand will match if demand remains at its current trajectory. There would be a shortage of about 20 percent if demand accelerated and a surplus of about 30 percent if demand lost momentum.

As noted earlier, we did not separately analyze the supply-and-demand balance for 150-mm and 200-mm wafers. (Supply for 200-mm wafers is expected to be tighter than for 150-mm wafers because of the challenges inherent in the ongoing shift to 200-mm manufacturing.) We also did not consider what percentage of wafers would meet the high standards for automotive MOSFETs. Therefore, we may overestimate supply in our scenarios unless manufacturers master the 200-mm transition much faster than expected. Furthermore, we did not consider the impact of SiC wafer demand related to non-BEVs. We excluded them because the penetration of SiC in the powertrains of such vehicles is expected to be lower than that for BEVs.

Taken together, these scenarios suggest that demand levels alone will not determine whether a SiC wafer surplus or shortage develops and that wafer supply is also a critical factor. What’s more, the supply-and-demand imbalance could vary for different wafer grades. Since automotive MOSFETs are in greatest demand but also the most difficult to manufacture, shortages are most likely within this category, especially if semiconductor companies cannot overcome the current quality issues.

If an oversupply does develop, manufacturers that produce 200-mm wafer equivalents may be in the strongest position because their offerings deliver the greatest cost benefits. Those suppliers that produce only 150-mm wafer equivalents could be consigned to second place.

It is too early to determine if one of the scenarios is more likely to emerge than another. The main point is that industry leaders should consider all possibilities when contemplating the SiC market’s future and be mindful of supply-and-demand trends, particularly those related to wafer yield. Simply monitoring nameplate announcements is not a reliable way to gauge future supply.

The SiC industry is proactively addressing the new demand stemming from growth in EVs, even though uncertainty abounds about how it will evolve. No matter what scenario materializes, demand for SiC wafers will continue to grow and remain robust. Simultaneously, competition will intensify for technology, quality, and price leadership, with wafer suppliers continuing to make massive investments in improvements. Incumbents face competition from emerging companies and will benefit from ensuring that the shift to 200-mm technology delivers the expected cost advantages to maintain their technology leadership. Meanwhile, emerging suppliers must focus on iterative learning to close the technology leadership gap against incumbents. For all industry stakeholders, the next few years will be a challenging but exciting time to capture opportunities.